Our Story

2025: The product line of High Vacuum tritium compatible products is further extended with 1/4Inch to 1.5 Inch products. Analytics on Protium/ Deuterium and Tritium for the Fuison-Industry is extended with a dedicated Raman Spectrometer.

2024: Machine building and lab building projects for major clients in the nuclear field were brought on the way. In parallel, the development of an industrial 3D printer for a dental project was established and late 2024 spun off in an own entity (www.adartys.com). Semi-conductor chip filling for customers in the nuclear battery sector is established.

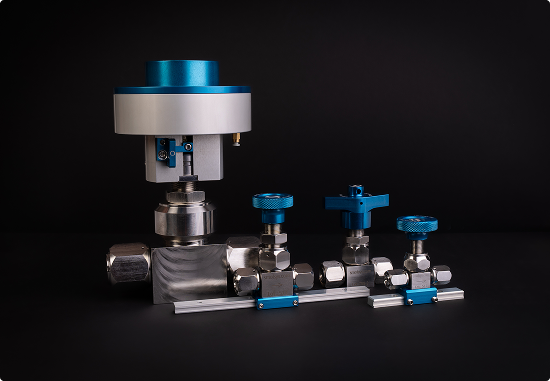

2023: Tritium compatible High Vacuum valves are developed and tested, a new, automated laser machine for our own production of Gaseous Tritium Light Sources is developed. A new all magnetic driven syringe type pump is developed. The product range is extended with the glow sensor, an analytic solid state scintillation device for the measurement of Tritium concentration.

2022: Automation projects on tritium handling and High Vacuum Technology. The GTLS product range is extended by the PLP, an insert that allows perfect daylight/ night visibility. Up-cycling of GTLS production leftovers was introduced so recycled tritium can be directly re-entered in the production cycle. The medical department is spun off under the name Yalosys (wwwe.yalsosys.com), to provide it the necessary focus. Yalosys grew into a world renown solution provider for complex laser glass processes/ laser welding and nano-hole drilling.

2021: Tritium handling and filling rig construction for customers in Asia

2017-2020: Engineering and building of manufacturing machines, establishing processes for GTLS production. Invention and upgrade to high pressure GTLS loading system. A dedicated med-tech division in glass-glass laser welding is established. Internationally funded projects can be started on this topic.

2016: After relocating the company to Lucerne, a very safe way to set up such a production for tritium was found in the form of a modular «Plug & Produce» pop-up production cell (laboratory). Since it was proven to be optimal for tritium and high-compliance work, it became smolsys’ trademark and is already in use by customers working with tritium. A dedicated medical department was established for glass-glass short-pulse laser fusion experiments.

2014: The company was founded in Zürich by specialists in the tritium business to peruse the dream of providing the world with new tritium products and technology, mainly also tritium powered glass implants and IoT sensors. I the first month, planning and engineering of the machines and processes started.

Our visionary inspiration Sandro M.O.L. Schneider, initiator and

co-founder of smolsys

For more information

For more information, please don’t hesitate to contact us. We’re here to assist with any questions or provide additional details to help you make informed decisions. Reach out today, and let’s connect!

Please mention the respective article number.

For more information

For more information, please don’t hesitate to contact us. We’re here to assist with any questions or provide additional details to help you make informed decisions. Reach out today, and let’s connect!

Please mention the respective article number.