3H Tritium Solutions

Tritium is a radioactive isotope of hydrogen. It is used in medical applications (e.g. drug labelling), in luminescent light sources for watches and optics, and as a tracer in geological groundwater monitoring.

Nuclear fusion uses it alongside the other hydrogen isotope, deuterium, for power generation experiments. Tritium is also being explored for battery applications—another promising field of research.

In all these applications, safe and precise handling of tritium gas is essential.

Isotope Handling Equipment

Isotope Handling Equipment

Tritium Valves & Fittings

Specially designed and manufactured tritium valves and components. Based on our long experience in tritium handling.

Tritium Ultra Syringe Pump

Custom-specific syringe pumps with magnetically driven pistons.

Protium/ Deuterium/ Tritium Ultra Syringe Pump

The smolsys «Isotope Ultra-Syringe Pump» enables steady and highly controlled gas compression and transfer. It covers a pressure range from low mbar levels up to 100 bar, depending on process requirements. All pumps are built on a common base and can be adapted to customer-specific needs. Manually operated or fully automated versions are available.

The pump plunger is magnetically driven. The design contains no rotary seals to the environment, resulting in a hermetically sealed system.

The pump housing is vacuum-vented to an external bypass system or scrubber, in case traces of gas pass the plunger seals. This enables closed-loop gas handling.

Multiple syringe pumps can be combined to create a continuous gas flow system, similar to a piston pump. The loading and pressure cycle can be precisely controlled. Real-time process data can be integrated into the pump control to dynamically adjust the gas flow according to actual process conditions.

Benefits of the smolsys Syringe Type Pump System

- Accurate, process-controlled pressurization

- Stable gas flow or pressure (from mbar to bar)

- Slow-moving components

- High temperature stability

- Maximum safety in isotope gas handling

Tritium Custom Equipment

Custom isotope loading vessel, double-walled, with anti-permeation coating.

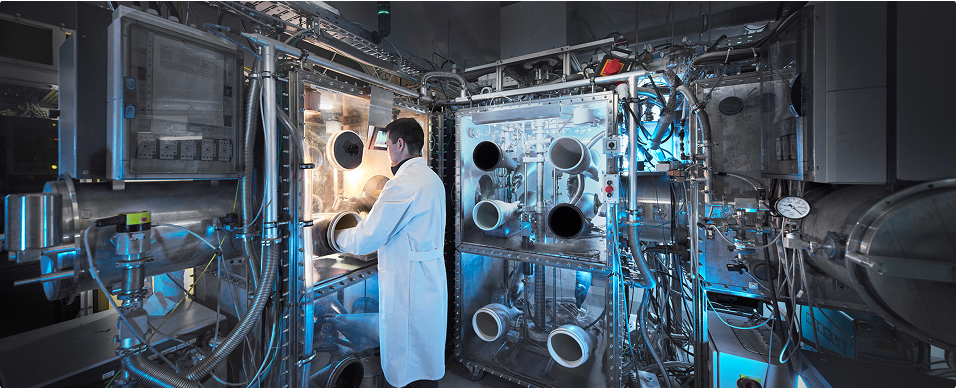

Tritium INERT GAS GLOVEBOXES

Tested and approved through years of Beryllium and Tritium handling at KIT and GVT in Karlsruhe, our glove boxes combine smart design with modularity and versatility. They feature interfaces compatible with various other box types and are based on a flexible general module. This allows an easy integration of custom-specific requirements, such as inert gas cleaning systems, sensors, PLC automation, and interlock programming (e.g. for shuttling liquids through the interlock).

The standard frame is made of stainless steel and the windows are made of acrylic, tempered multi-layer glass. Other custom materials are available upon request.

Tritium Analytics

Tritium Analytics

Tritium Concentration / Pressure Sensor

Function:

The sensor uses tritium beta radiation to generate radioluminescence, which is then measured by photodiode (solid scintillation principle).

It features:

- Wide concentration range

- Fast response time

- Pressure range: 0–20 bar

- Temperature range: 0–50 °C

Tritium MICRO RAMAN SPECTROSCOPY

KIT (Karlsruhe Institute of Technology) licensed Raman spectrometer by smolsys

- Tested at KIT laboratory in the KATRIN experiment

- Plug & Produce setup - ready in just three clicks in their 25g Tritium loop

- Robust and compact, for inline use (max. 1 bar; higher pressure on request)

- Temperature range: 0–50 °C

Available September 2025

Request more information/ apply for test device

FAQ Micro Raman Spectrometer

Raman spectroscopy is not an absolute measurement but a relative one.

Raman spectroscopy is not limited by a % or ppm-ratio. You always have a detection limit on absolute quantities, e.g. mbar of species X.

If your sample pressure is for example 10mbar but made up from a pure gas, you can detect that. If you fill the sample volume with 1390 mbar of “some other” gas (mixtures) – all must be Raman active – you can still detect that initial 10 mbar gas.

By that, a ppm ratio is only a sensible figure if you state at which total sample pressure you are working. 10 mbar in 100 mbar total pressure translates to 10 % detection limit while 10 mbar in 1390 mbar translates to 0.7 % but still the same amount of gas.

In addition, your detection limit depends on how long you expose per single spectrum AND how many single exposure spectrums you are combining.

1.Is it used with dilute carrier gases- nitrogen/argon/neon etc...? What carrier / dilution gas shall we use?

Since all noble gases are not Raman-active, you cannot detect those if uses as a carrier gas. The system is only detecting constituents in the range of approx. 1550 1/cm (580nm) to 4500 1/cm (700nm), translating to the molecules of interest. This is related to the spectrometer and laser wavelength used in the setup and tuned for the detection of hydrogen isotopologues. Therefore, there is no such thing as a trueness for any noble gas.

Regarding nitrogen, this molecule falls close to the signal region of interest for tritium. This is, why I would not recommend using N2 as a purge gas since this might interfere with a potentially weak signal of tritium. If you are willing to do some more elaborated processing of your data involving peak fitting algorithms, you will still be able to separate those peaks but the overall since there is an approx. 5 nm “distance” in the spectrum. Despite nitrogen can be easily detected, trueness for nitrogen is not specified. You would need to introduce a clean and pure sample of nitrogen at known pressure(s) and the same pressure of clean and pure hydrogen or, if possible, a 1:1 mixture of N2/H2 determining the efficiency of detection for N2.

Within the capabilities of the system, there is a negligible variation of the trueness, so the +/- 2.5% CL can be seen as a global value.

2.Does the trueness vary with pressure or is it a blanket +-2.5% to apply when creating confidence limits?

The Raman method is sensitive to absolute gas amounts translating to absolute pressures in a sample volume. For any “close to real time” measurement We do not recommend single species to be below a partial pressure of 5-10 mbar. Note, that any fluctuation of a single gas species during a single spectrum-take will only be detected as an averaged signal with no time resolution. So standard setting, the time resolution is about 1 minute.

If you chose to e.g. pull a static sample of your sample and invest more time (read: 2-5 h) you might be able to extract signals of approx. 0.5 – 0.8 mbar gas. This was shown in https://www.mdpi.com/1644198 where the limits under more “real world” conditions are examined.

Taking all measurements and subtract 100% minus the sum of all others would not improve the situation since all detectable gas is already considered to be “100%”, especially since you would have to apply an error propagation. Consider 10 mbar partial pressure as a safe detection limit for standard settings.

3.Is the software provided as a download and is it automatically updated online?

It is ll pre-installed and ready to go. Also we can then provide future firm and software update.

4.What other characteristics are there beyond below 2mBar of the gas to be sensed: such as temperature, humidity, and other non-hydrogen isotope chemical species?

This can be integrated by adding other sensor/ data and summarized in a custom PLC, but is not (yet) part of the function of the device

5.How does the pipe diameter influence the reflection and this the backround noise

6.What is the minimum distance to the opposite wall of the chamber to still have a good background and not too much reflection..

https://www.tandfonline.com/doi/full/10.1080/15361055.2023.2166779#d1e279

Requirements Engineering and Process Development

Requirements Engineering and Process Development

By far the most difficult and time-consuming step in a project is identifying and refining the exact requirements.

This is where we support you—guiding you through an in-depth requirements engineering process.

At the end stands a clear picture of exactly how all processes and equipment need to be built and function.

We offer this service for tritium, gas/vacuum handling, and machine building in nuclear and medical applications.

Custom Machine Building and Automation

Custom Machine Building and Automation

In addition to engineering and building automated machines and systems, we can integrate our own off-the-shelf tritium handling products, such as face-sealed all-metal bellows valves and other high-vacuum components, magnetically driven syringe pumps for high-pressure applications, and our new in-line tritium concentration sensor.

Applications:

- Mobile radioisotope handling laboratories

- High-temperature heating

- Automation of hydrogen gas handling systems

Plug & Produce Isotope Labs

Plug & Produce Isotope Labs

The modular labs can be adapted to existing pre- or post-processes without the need to repeat full radiation safety assessments or licensing and risk analyses. If required, access control, personnel monitoring, and air/environment surveillance systems can be added. All system data can be integrated into existing production or security control systems and, if requested, accessed via the cloud (if requested). Fire safety is set to EI 90 by default.

The RMC Method of Tritium handling: Fusion Science and Technology

Our approach

«Plug & Produce» production units – the most efficient and safe way we know.

Working with tritium for decades, we learned that we need something that protects personnel while ensuring that tritium release to the environment is kept to the lowest achievable level. Also, since we work in private industry rather than in a science lab, we knew that processes need to be cost-effective, and machines and automation systems reliable.

We found that the best way to combine these requirements is what we call a «Plug & Produce» pop-up production cell. It consists of a self-contained unit (a specialized lab container) that includes the critical process, machinery, and measurement systems. The unit itself creates a protected environment. Conditions inside are predictable and continuously monitored. Tritium-in-air concentrations (T₂ and HTO), temperature, airflow, air quality, oxygen levels, humidity, and any other parameter need to run a controlled and reliable process.

The benefits of our smolsys Plug & Produce production units:

- Maximum flexibility

- Shortest time to production

- Easy monitoring of safety and performance indicators

- Fast setup as an additional safety zone

- Fully transportable

- Pre-established compliance with regulatory requirements

- Clearly defined and specified interfaces to ist surrounding environment

- Easy adaptation to changing needs—no retrofitting of existing facilities required

- Built-in safety: EI 90 fire protection and advanced ventilation system with 25-fold air exchange per hour

Tritium Microparts manufacturing

Tritium Microparts manufacturing

GASEOUS TRITIUM LIGHT SOURCES

GTLS (Gaseous Tritium Light Sources) are widely used in exit signs, watches, and gun sights. smolsys Ltd. offers custom manufacturing of Gaseous Tritium Light Sources (GTLS) according to your specifications. GTLS are manufactured from glass capillaries whose inner walls are coated with a phosphorescent pigment. The capillaries are then pressure-filled with tritium gas. The gas acts as an energy source, providing the power for the lights. GTLS can be manufactured in different colors and brightness levels. They provide self-powered light for decades and withstand harsh environmental conditions. We test and certify GTLS according to MIL-SPEC and ANSI standards.

ENGINEERING SOLUTIONS

- Nuclear Engineering

- Tritium handling

- Tritium analytics

- Radiation Safety and Transport

- Engineering

- LabView

- AutoDesk

- SolidWorks

- Functional Safety

- Process risk assessment

- ATEX Design, Preparation and Installation

- Machine building & automation

- Components testing

- Components & Equipment manufacturing

For more information

For more information, please don’t hesitate to contact us. We’re here to assist with any questions or provide additional details to help you make informed decisions. Reach out today, and let’s connect!

Please mention the respective article number.

For more information

For more information, please don’t hesitate to contact us. We’re here to assist with any questions or provide additional details to help you make informed decisions. Reach out today, and let’s connect!

Please mention the respective article number.